INDUMATIK.

AUTOMATION FOR EVERY

MACHINING CENTER

Indumatik - The german way of automation.

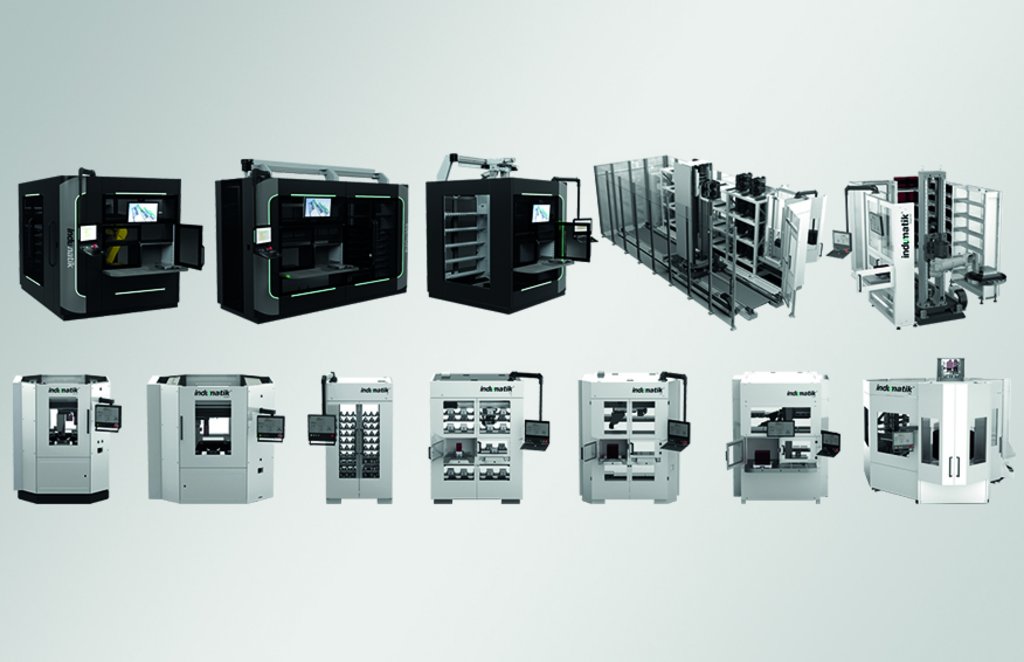

We automate your machining center with our Indumatik systems! Regardless of whether you want to clamp your workpieces on a pallet and vice or handle them directly, you can choose from 15 different systems that have been used thousands of times.

From 8 - 500 kg handling weight, we have your system on offer. Looking ahead to 2025, we are planning an Indumatik 1500 L with a handling weight of 1500 kg.

WHAT IS INDUMATIK?

Indumatik is the pioneer of milling machine automation. Over 20 years ago, Indunorm launched the first Indumatik as a pallet changer with a cabinet system ("in the cabinet"). At the time, this innovation was still ridiculed. Today, the automation of milling machines and machining centers has long been established. Indunorm has used the experience of the past decades to further expand its automation solutions in order to meet all customer requirements. We now offer over 15 Indumatik systems for the automation of machining centers. We have been the market leader in Germany for years. We not only supply end customers, but also have strong links with many machine tool manufacturers who also rely on our solutions!

Unmanned production

Unmanned production.

Thanks to unmanned operation, especially at night and at weekends, production capacities can be used efficiently and increased without having to rely on additional workers. The number of skilled workers is automatically reduced.

Get advice now

Unmanned production.

Thanks to unmanned operation, especially at night and at weekends, production capacities can be used efficiently and increased without having to rely on additional workers. The number of skilled workers is automatically reduced.

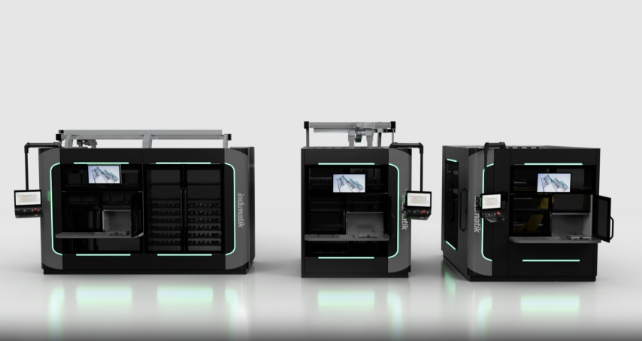

THE NEW INDUMATIK GENERATION.

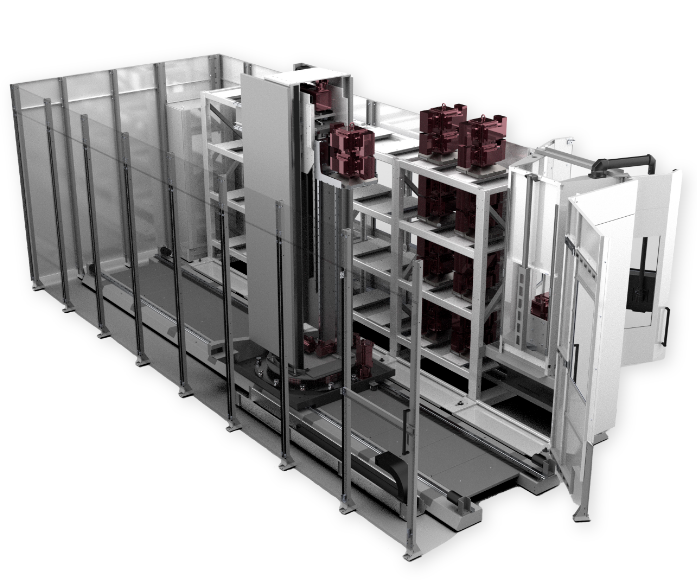

The new Indumatik modules VL 40, VL 80 and VR 70 set the standard for flexible automation solutions. These latest achievements enable customized configurations for parts and pallet handling, tool extensions and multi-machine operation. Their combination opens up possibilities for hybrid systems that offer optimum adaptation to diverse production requirements.

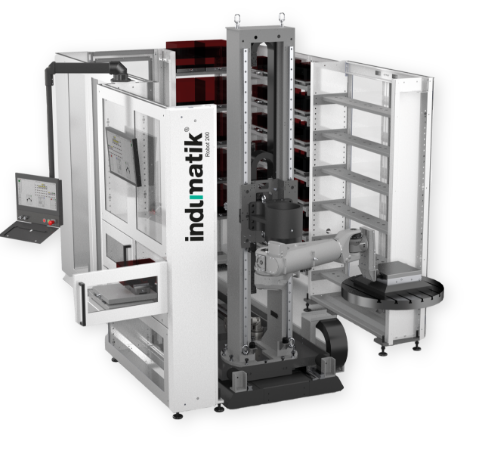

INDUMATIK - VL 40.

The Indumatik VL 40 offers a modular automation solution. This compact system integrates a linear axis robot that handles pallets and workpieces directly. With this hybrid solution, pallets up to a size of 200 x 200 mm, workpieces up to a depth of 120 mm and a handling weight of 40 kg are possible. The Indumatik VL 40 is ideal for small batch sizes from one piece upwards. The VL 40 can also be set up very quickly for individual parts. It can be modularly expanded and can also operate several machines.

INDUMATIK - VL 80.

The modular Indumatik VL 80 can be equipped with a variety of different racks and shelves, both for different pallets and pallet sizes up to 320 x 320 mm and for workpiece handling up to a depth of 200 mm. The double storage and retrieval station is used for the ergonomic feeding of workpieces weighing up to 80 kg. The shelf trays for storing and retrieving the workpieces are configurable. This system can also be expanded modularly and serve several machines. It can also be used as a tool changer!

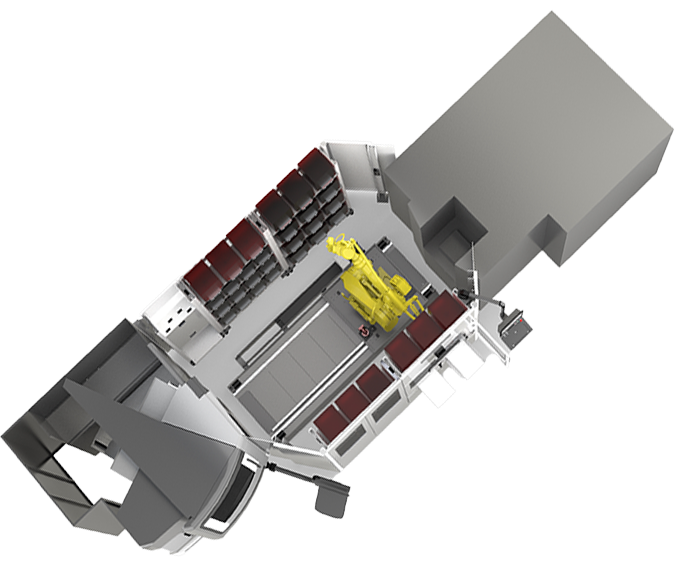

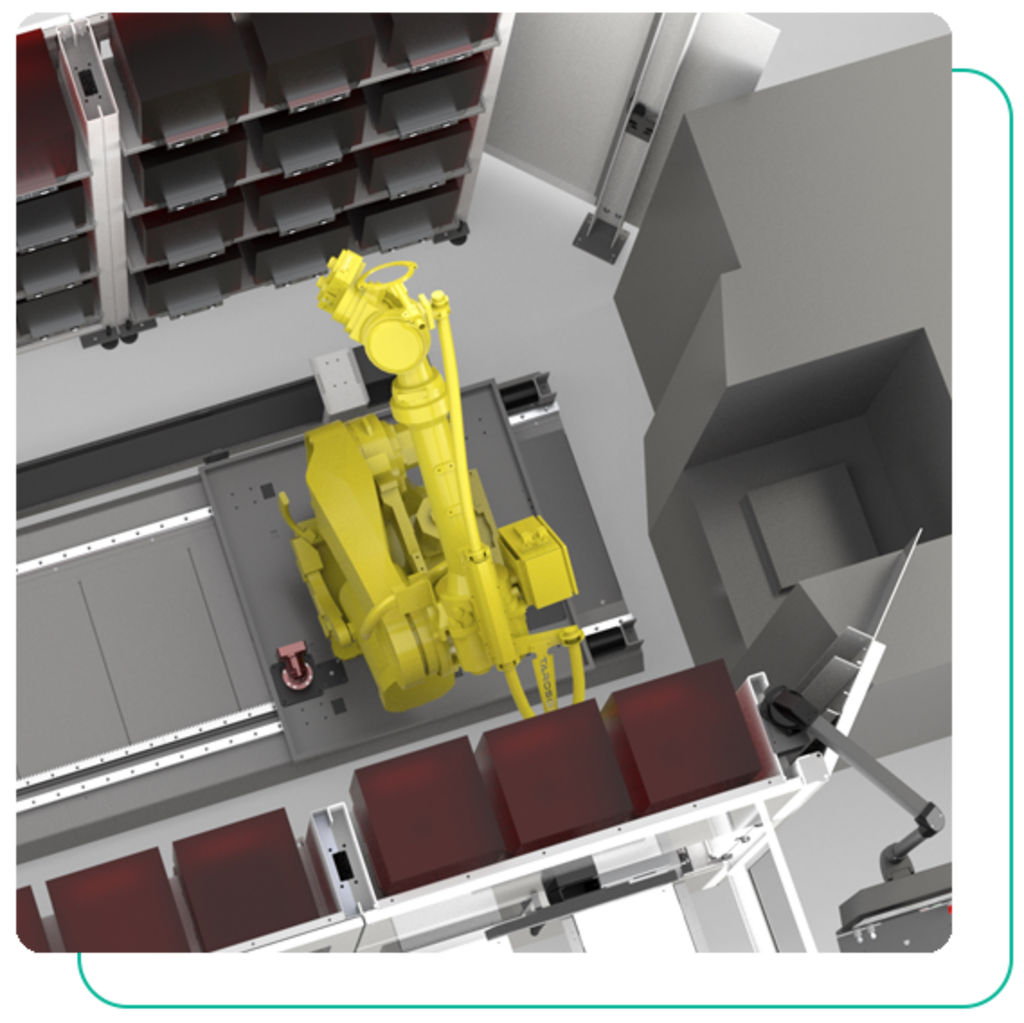

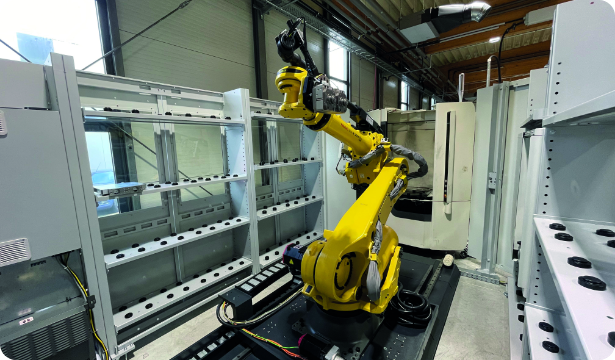

INDUMATIK - VR 70.

With an articulated arm robot from Fanuc, the Indumatik VR 70 can handle both pallets and workpieces directly. The handling weight is 70 kg. Individually assembled in modular design, the system can be equipped with a variety of different racks and shelves, both for different pallet types and sizes and for workpiece handling.

Our classics

PROVEN SOLUTIONS.

With over twenty years of experience in the development and assembly of milling machine automation, we can proudly claim that our solutions have proven themselves in numerous production environments.

Our systems for parts and pallet handling, tool extensions and multi-machine operation are characterized by their reliability, precision and versatility. To date, over 2,000 machining centers have been equipped with Indumatik for automated operation.

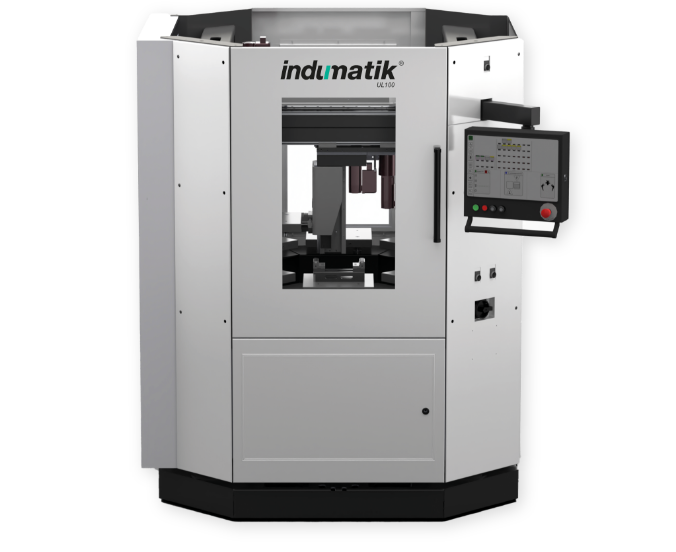

INDUMATIK - UL 100.

Transfer weights of up to 100 kg can be automated effortlessly with the Indumatik UL 100. Despite its simple operation and cost-effective interface, the machine tool can optionally select different positions in a chaotic manner. With the optional second level, the number of pallet spaces can be significantly increased.

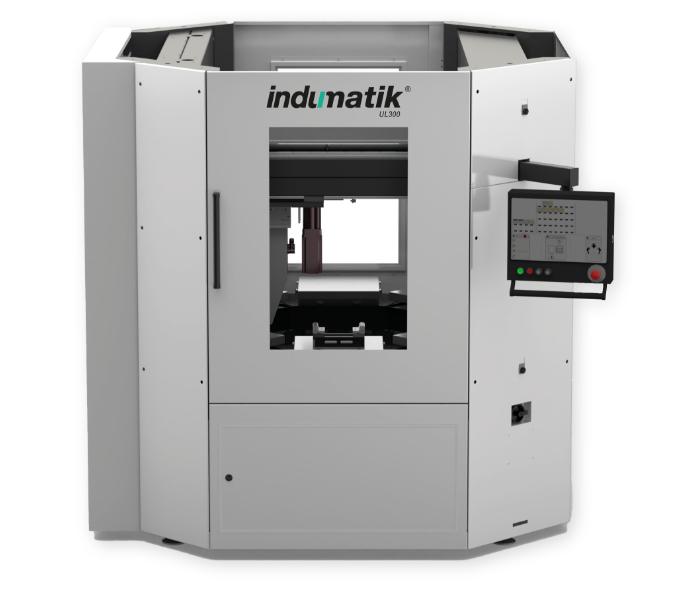

INDUMATIK - UL 300.

To handle large workpieces and heavy weights in a small space, Indunorm Bewegungstechnik has further developed the proven technology of the Indumatik UL, making it even more flexible in terms of workpiece size and weight. 1 kg or 300 kg, the Indumatik UL 300 handles your workpieces quickly and easily.

INDUMATIK - L 8.

With a footprint of less than 1m2, the Indumatik L 8 is the most compact of the automation systems. This automation is the first choice for electrode handling or medical technology in particular. Flexibility and modularity in the smallest of spaces, even where space is at a premium.

INDUMATIK - L 30.

The Indumatik L 30 - the original of the Indumatik L series - is a closed machine for changing workpieces. This handling system has been tried and tested for over 10 years as a compact, reliable system. Milling, clamping and automation are elegantly combined with a high number of pallet positions in a compact design.

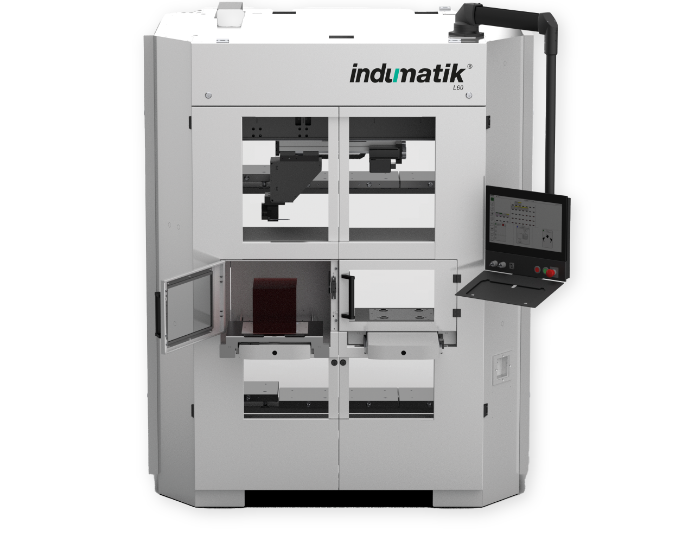

INDUMATIK - L 60.

With the development of the Indumatik L 60, manufacturing practice has been consistently taken a step further. The Indumatik L 60 not only handles pallets weighing up to 60 kg, this system can also be used as an optional workpiece automation system. The use of sub-grippers and pre-pallets and a magazine division as required means that the L60 offers the greatest possible flexibility.

INDUMATIK - L 120.

The Indumatik L 120 is the ideal solution for everyday use in machining and production. Designed for a handling weight of up to 120 kg, the Indumatik L 120 meets the requirements of our customers in a future-oriented way. Thanks to its modular design, the automation can be adapted to one or two machine tools using numerous tried-and-tested options.

INDUMATIK - R 165.

The Indumatik R 165 is a flexible automation solution for CNC machines. With an articulated arm robot, both workpieces and pallets for clamping fixtures can be automatically loaded and unloaded in a machine. The robot can pick up various grippers and, with the help of prepallets, can also pick up various pallets. To reduce unproductive downtimes, the robot picks up two grippers at the same time for a quick changeover, e.g. of workpieces into and out of the processing machine.

INDUMATIK - 200 L.

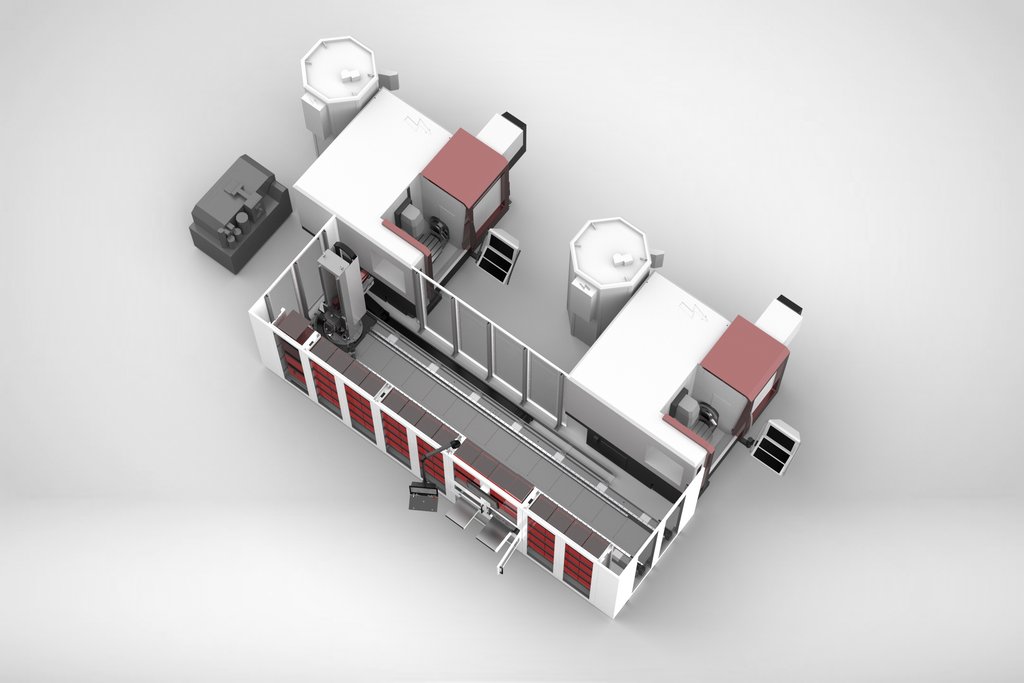

The use of the Indunorm BFW 1100 and BFW 1400 floor trolley makes the Indumatik linear axis robots even more flexible to use. Any number of storage locations, different machining centers and / or different technologies can be combined with an Indumatik to form a production cell. The cell can continue to grow, so that future requirements are already provided for.

To the product

INDUMATIK - R 200.

Half of our Indumatik R 200 linear axis robot consists of a Scara arm and the other half of a linear axis system. This is moved on the floor by a specially developed 7th axis. The system is characterized by a very compact design and a long reach. Depending on the project, the footprint of the system is reduced by approx. 50% compared to the classic articulated arm robot and the available space can be used on several levels thanks to a vertical linear axis.

INDUMATIK - 500 R.

With the new Indumatik 500 R, large and heavy workpieces can be inserted into machines, even if long strokes are required. The Indumatik 500 R combines different machines, technologies and pallet sizes into one production cell.

INDUMATIK - I 41.

The number of tools is no longer a limiting factor when it comes to productive manufacturing. The tool changer and automatic workpiece feed complement each other to form an efficient unit. With up to 220 tool positions and flexible equipment for HSK, SK, Capto, BT and CAT holders, the Indumatik tool changer with its sophisticated design is much more compact than a chain magazine.

INDUMATIK - I 45.

With the Indumatik Toolchanger I45, the internal tool magazine of the processing machine can be easily extended. Thanks to the flexible equipment for HSK, SK, Capto, BT and CAT holders, you are equipped for every requirement. With up to 400 tool positions, you always have the right selection of tools to hand. This powerful system increases the efficiency and productivity of the processing machine.

Extensive applications of Indumatik

NUMEROUS APPLICATIONS.

Precise parts handling, efficient pallet handling and flexible multi-machine operation optimize your material flow and increase productivity. Tool extensions maximize the functionality of your systems, while hybrid systems offer maximum flexibility.

Our grippers - be it the fork gripper, parallel gripper or zero-point gripper - guarantee safe and precise handling of a wide range of workpieces. This is complemented by transfer carriages, sub-grippers and screwdriving stations, which further increase the precision and efficiency of your production.

Our automation solutions

AUTOMATION BY MANUFACTURER.

Indumatik is the key component for automation solutions that can be seamlessly integrated into various manufacturer environments. Our systems offer universal compatibility, making it possible to implement automation functions for a wide range of manufacturers and machines. No matter which manufacturer you prefer, Indumatik offers you the flexibility and efficiency to automate and optimize your production.

Kundenlösung Feldmann

Kundenlösung Feldmann

FELDMANN DOOR SYSTEMS

Indunorm installed an Indumatik robot cell that combines a vertical DMU 60 eVo and a horizontal NHX 4000 to form a fully automated production cell. With a Fanuc R-2000i articulated arm robot, extended by the BFW 800 floor-mounted trolley as the seventh axis, all seven axes could be centrally controlled and monitored. The solution allowed the use of pallets of different sizes and the retrofitting of automatic doors and media connections to equip the machines with the necessary automation interfaces.

Kundenlösung Jongen

Kundenlösung Jongen

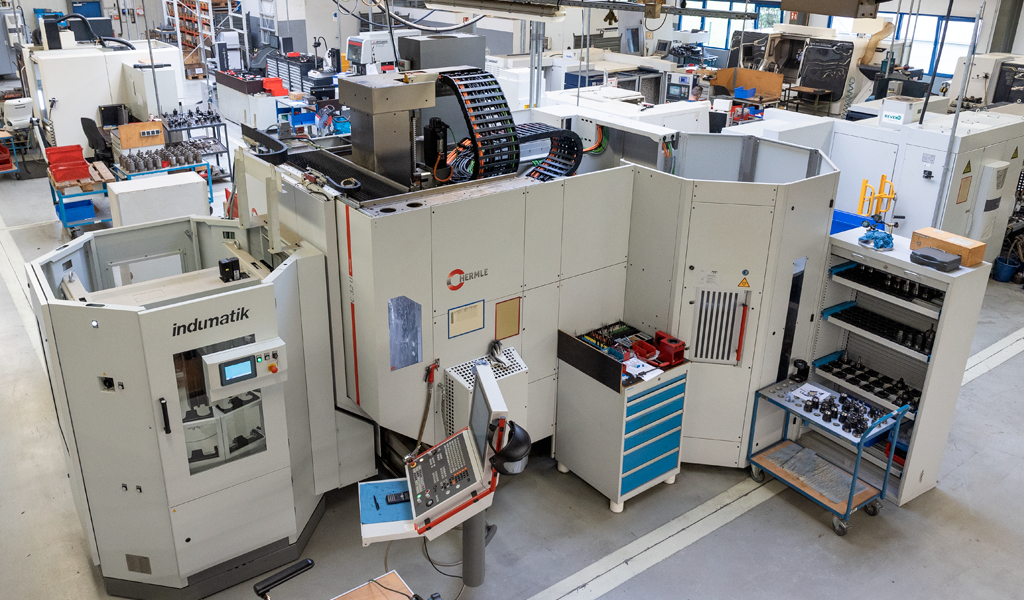

JONGEN

The search for an effective solution led Jongen to Indunorm's Indumatik technology. Due to the user-friendly interface, the low maintenance requirements, the excellent process reliability and the simple implementation, the choice fell on an Indumatik Ultralight. In the meantime, Jongen has automated four Hermle machining centers with Indumatik Ultralights.