INDUMATIK - R 165.

R 165 - Flexible with two grippers

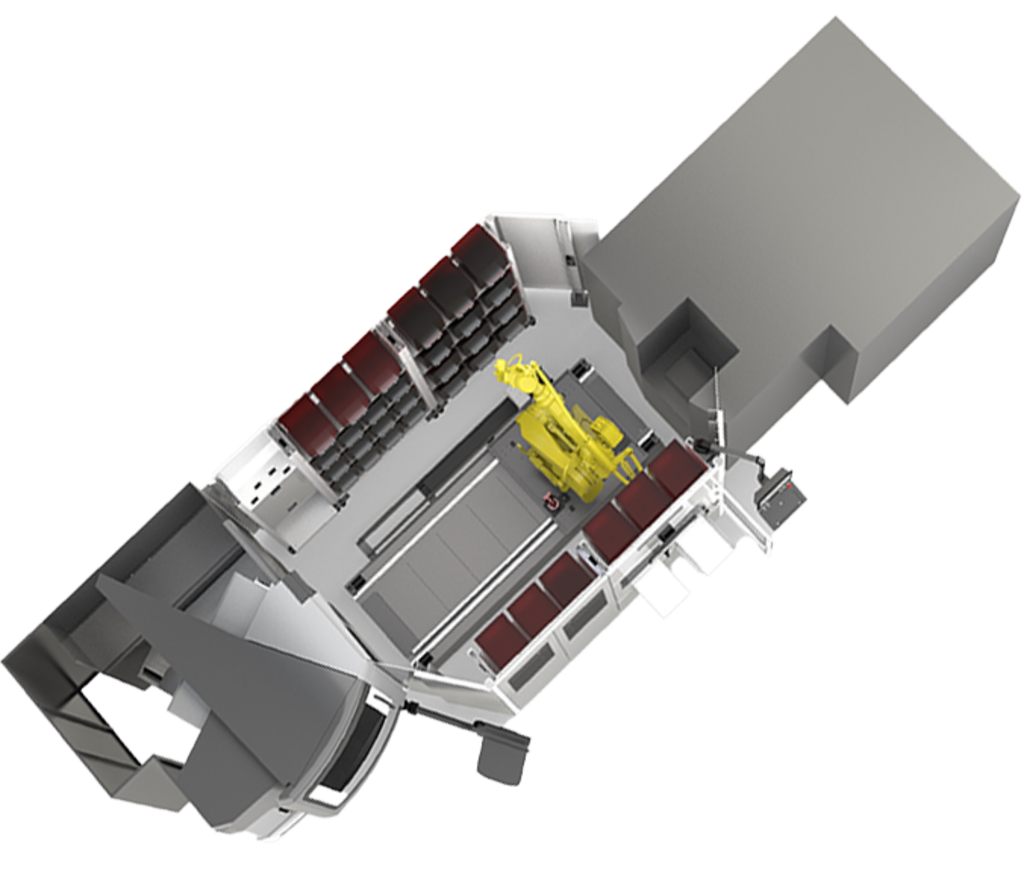

The Indumatik R 165 is a flexible automation solution for CNC machines. With an articulated arm robot, both workpieces and pallets for clamping fixtures can be automatically loaded and unloaded in a machine. The robot can pick up various grippers and, with the help of prepallets, can also pick up various pallets. To reduce unproductive downtimes, the robot picks up two grippers at the same time for a quick changeover, e.g. of workpieces into and out of the processing machine.

GROUND RUNNING GEAR BFW.

The floor trolleys were developed to be able to move various robot applications. This means that the robot is no longer statically limited to one position in the Indumatik system, but has an additional axis for a larger movement radius thanks to the floor-mounted undercarriage. Originally only used in the Indumatik systems, we now also offer the floor trolleys separately for your robot application and have four standard sizes available. The floor trolleys have a very flat and compact design and are therefore impressive compared to other solutions, which are often not expandable.

DRAWER STORAGE.

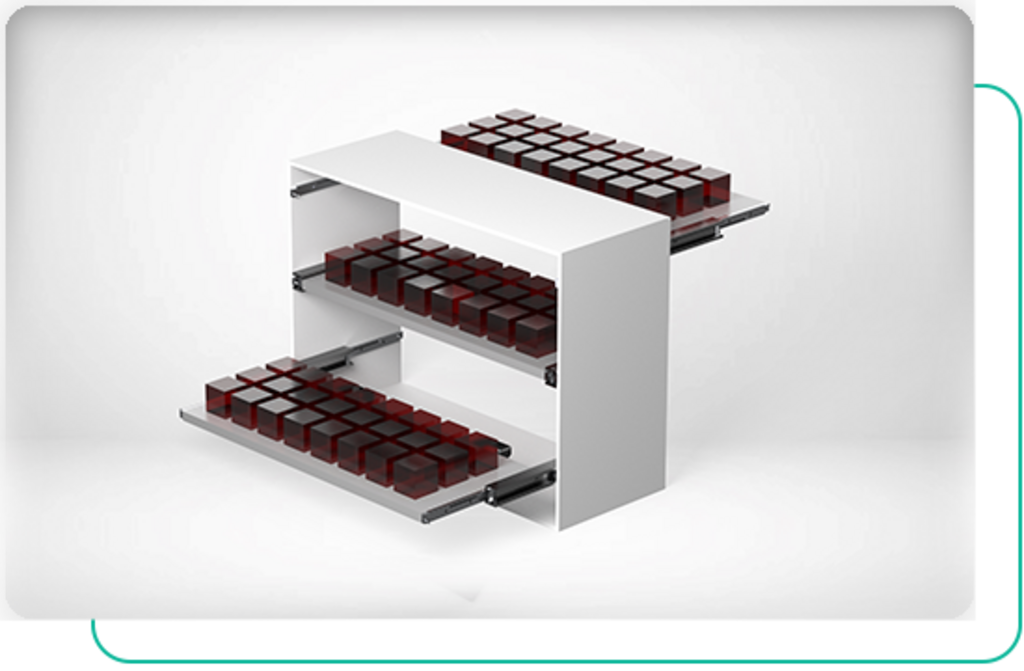

In order to operate shelves automatically, we have developed a telescopic rail that telescopes the drawer base completely out of the housing. This makes it easy to load and unload the drawer storage unit from both sides. The telescopic rail has been specially optimized by our engineers to meet the requirements of automated workpiece handling. This enables the operator to make full, efficient and ergonomic use of the drawer depth.

|

Dimensions [WxDxH] |

According to version |

|

|---|---|---|

|

Permissible transfer weight |

165 kg |

|

|

Pallet gripper |

zero-point gripper |

|

|

Sub-gripper or gripper options |

parallel gripper, fork gripper, tool gripper |

|

|

Storage location size [W x D] in standard |

Pallet size according to customer requirements |

|

|

Pallet spaces as standard |

Customizable |

|

|

Job management Operation |

Touchscreen optional host computer |

|

|

Interface |

Bus interface, I/O signals |

|

|

Storage/retrieval of the WS |

2-fold storage and retrieval station |

|

|

Floor-mounted chassis |

BFW1100 |

|

|

Multi-machine operation |

Flexibly expandable |