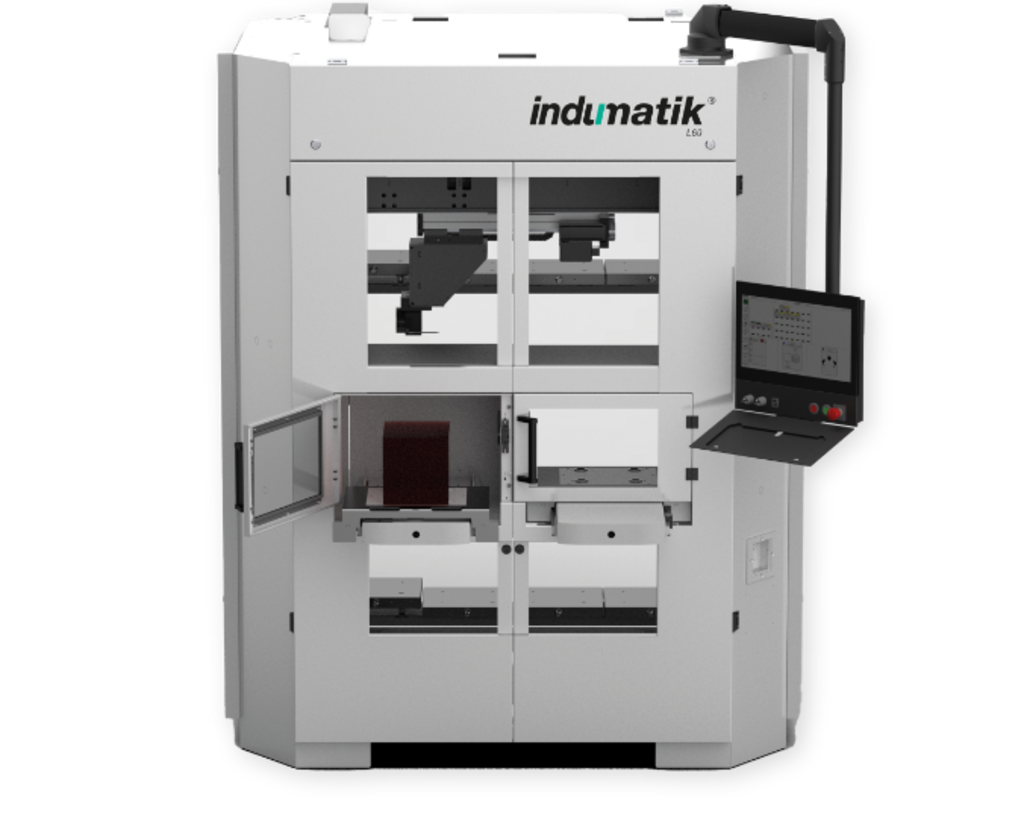

INDUMATIK - L 60.

L60 - Compact all-rounder

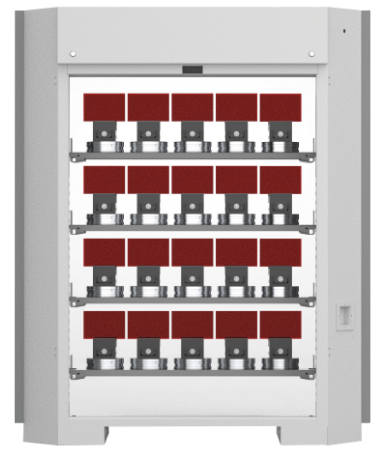

With the development of the Indumatik L 60, manufacturing practice has been consistently taken a step further. The Indumatik L 60 not only handles pallets weighing up to 60 kg, this system can also be used as an optional workpiece automation system. The L 60 offers the greatest possible flexibility through the use of sub-grippers and pre-pallets and a magazine division as required.

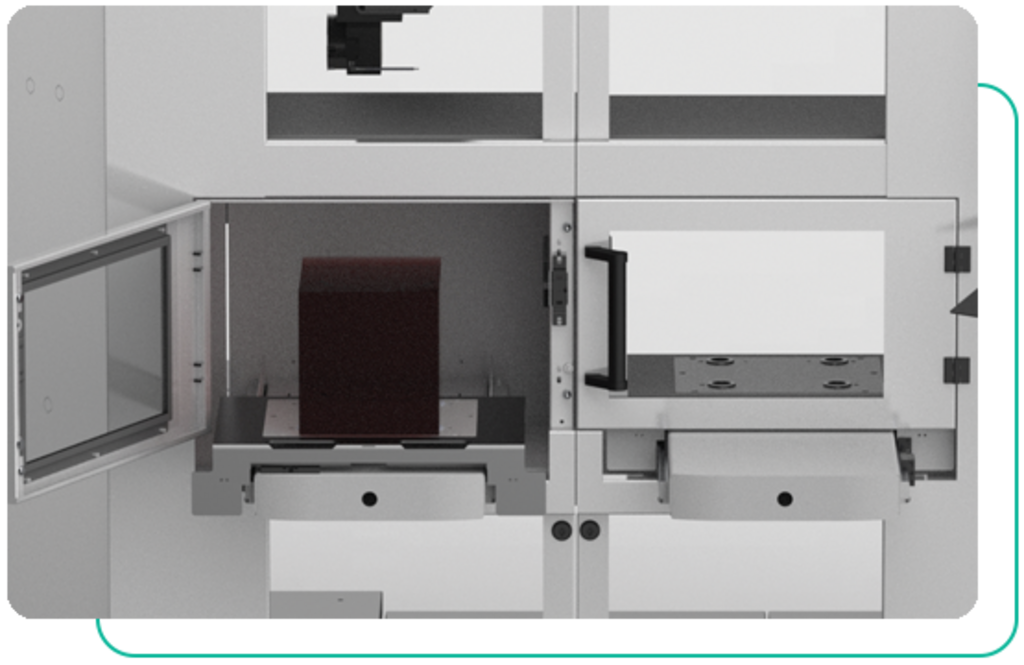

SLIDING TROLLEY.

For machine tools that can only be loaded from the front, we offer a sophisticated solution with the electric transfer carriage. You can switch between automated and manual operation in a matter of seconds. And all this without any disruptive installation on the hall floor, as the necessary mechanics are built into the transfer carriage.

ERGONOMIC STORAGE AND RETRIEVAL STATION.

The storage and retrieval station is integrated into the Indumatik L 60 as standard and enables loading during machining. The machine operator uses the storage and retrieval station while the processing machine is in operation to load the automated system. The storage and retrieval station is used to load and unload the pallets in two separate stations via drawers. Access to the two stations is enabled alternately.

INDUMATIK - L 60.

L60 - Consistently thinking ahead

With the development of the Indumatik® L 60, manufacturing practice has been consistently taken a step further. The Indumatik L 60 not only handles pallets weighing up to 60 kg, this system can also be used as an optional workpiece automation system. The L60 offers maximum flexibility thanks to the use of sub-grippers and pre-pallets and magazine partitioning as required.

|

Dimensions [WxDxH] |

1900 x 1590 x 2400 mm |

|

|---|---|---|

|

Permissible transfer weight |

60 kg |

|

|

Pallet gripper |

zero-point gripper |

|

|

Sub-gripper or gripper options |

parallel gripper, fork gripper |

|

|

Storage location size [W x D] in standard |

200 x 200 mm / 320 x 320 mm |

|

|

Pallet spaces in standard |

30 / 24 |

|

|

Direct workpiece handling option |

Available |

|

|

Job management operation |

touchscreen optional master computer |

|

|

Storage/retrieval of the WS |

2-fold storage and retrieval station |

|

|

Transfer carriage |

Optional |