INDUMATIK.

AT FELDMANN TÜRSYSTEME

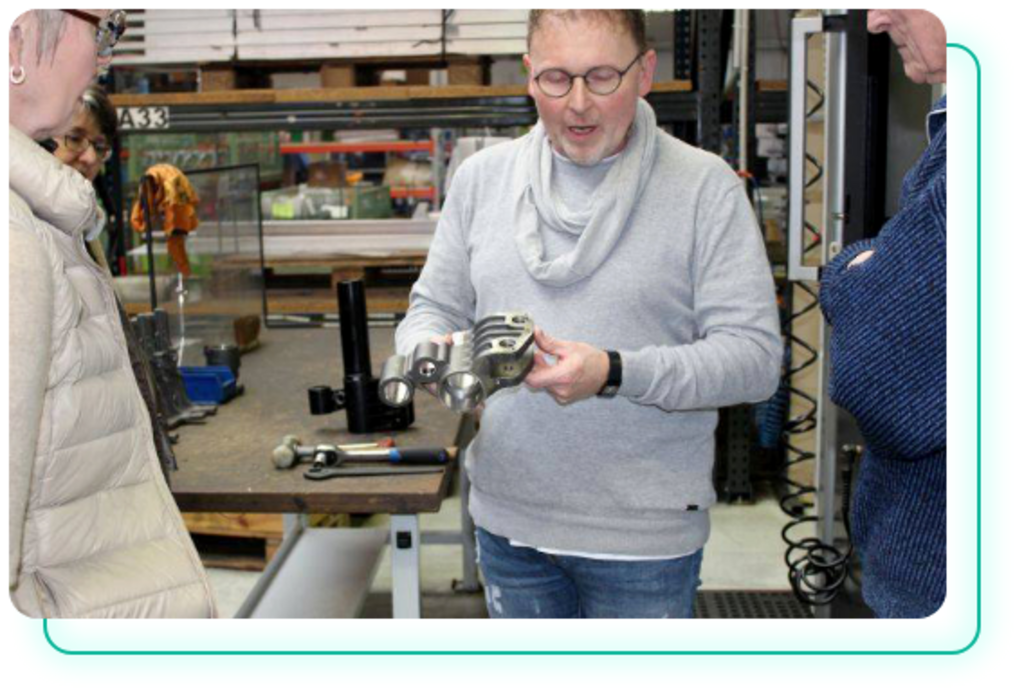

Today we look at the successful implementation of an Indumatik robot cell at Feldmann Türsysteme GmbH in Velbert. As a manufacturer of high-precision door systems for the passenger transportation sector, Feldmann is faced with the challenge of meeting the highest safety and quality standards.

The collaboration with INDUNORM Bewegungstechnik was aimed at meeting these requirements with advanced automation solutions.

Customer from the supply industry

ABOUT FELDMANN TÜRSYSTEME

Feldmann Türsysteme GmbH, based in Velbert, has established itself as a renowned manufacturer in the passenger transportation systems industry. The company specializes in the development and production of high-precision door systems used in public transport and other areas of passenger transportation. These products must meet the highest safety requirements, as they contribute directly to the protection and safety of passengers. Manufacturing such complex systems requires state-of-the-art CNC technologies and continuous innovation in the production processes to ensure precision, reliability and efficiency.

The challenge

The precise production of complex door systems consisting of around 4,000 individual parts,required a solution that not only enabled high accuracy, but also flexible and efficient production.The need to be able to produce outside of manned working hours posed a particular challenge.

Solution

Indunorm installed an Indumatik robot cell that combines a vertical DMU 60 eVo and a horizontal NHX 4000 to create a fully automated production cell.With a Fanuc R-2000i articulated arm robot, extended by the BFW 800 floor trolley as the seventh axis, all seven axes could be controlled and monitored centrally.The solution allowed the use of pallets of different sizes and the retrofitting of automatic doors and media connections to equip the machines with the necessary automation interfaces.

RESULT.

By implementing the Indumatik robot cell, Feldmann Türsysteme was able to significantly increase production efficiency while ensuring the safety and quality standards of its products. The machines run fully autonomously and enable production outside of manned times, which has led to a significant increase in productivity.