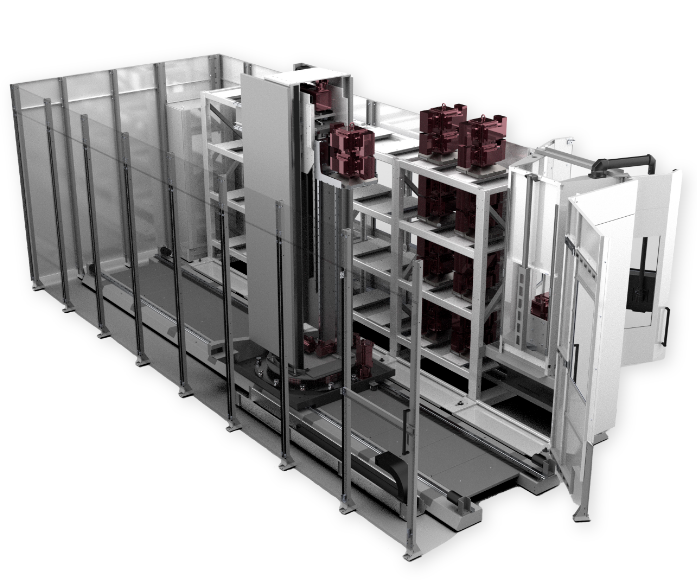

HYBRID SYSTEM.

The hybrid system combines pallet handling and parts handling. The rack elements are equipped with both pallets and workpiece carriers.

The workpieces are clamped onto clamping devices via pallets. For medium and large batch sizes, the workpieces are inserted directly via the workpiece handling system and processed in parallel with the other pallets in the mix.

This processing mix enables companies to achieve very long and automated processing machine runtimes.

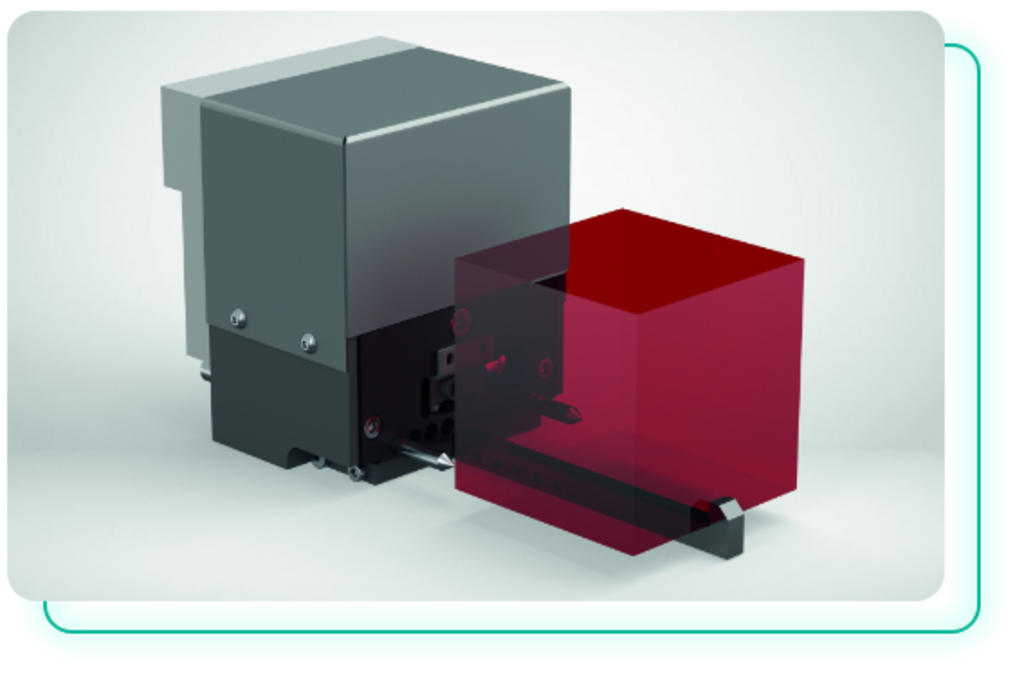

RACK MODULES.

Hybrid systems have a number of racking modules in which workpiece carriers or pallets can be stored. This allows different workpieces or materials to be processed simultaneously without delays or interruptions, and the racking modules of a hybrid system can be individually equipped to meet the specific requirements of the company. For example, rack modules can be equipped with special devices for unusually shaped workpieces or special materials.

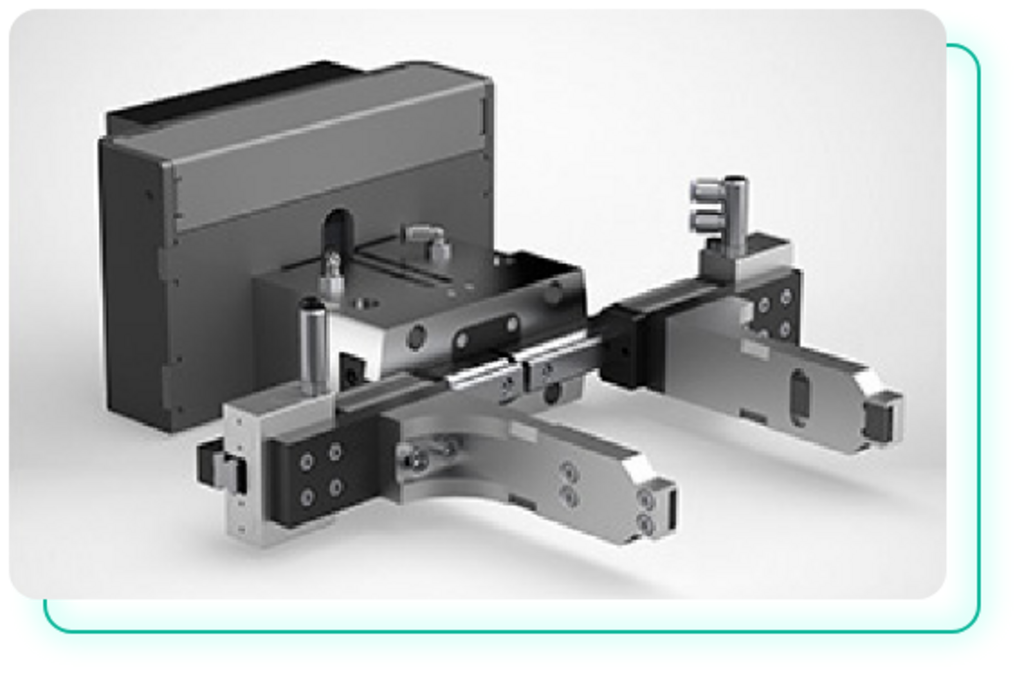

GREIFER BASIC.

The Basic gripper is used in conjunction with workpiece tableaus and has a 3-point contact and adjusts to the size of the workpiece to be picked up before the first workpiece is picked up.

The machine operator prepares the shelves and adjusts the holders to the width of the workpieces. The gripper moves under the workpiece, lifts it and actuates the integrated pneumatic drive. The workpiece is then aligned on the gripper and can be transported to the clamping device and deposited there.

After processing, the Basic gripper moves back into the clamping device in exactly the same way, picks up the workpiece and returns it to the same position on the shelf. The machine operator removes the finished part.

This workpiece handling can be operated either by a linear axis robot or by an articulated arm robot. However, the linear axis robot is typically used, for example in the Indumatik 200. In this application, pallet handling and workpiece handling are combined. A combination of pallet and workpiece handling is a hybrid system.

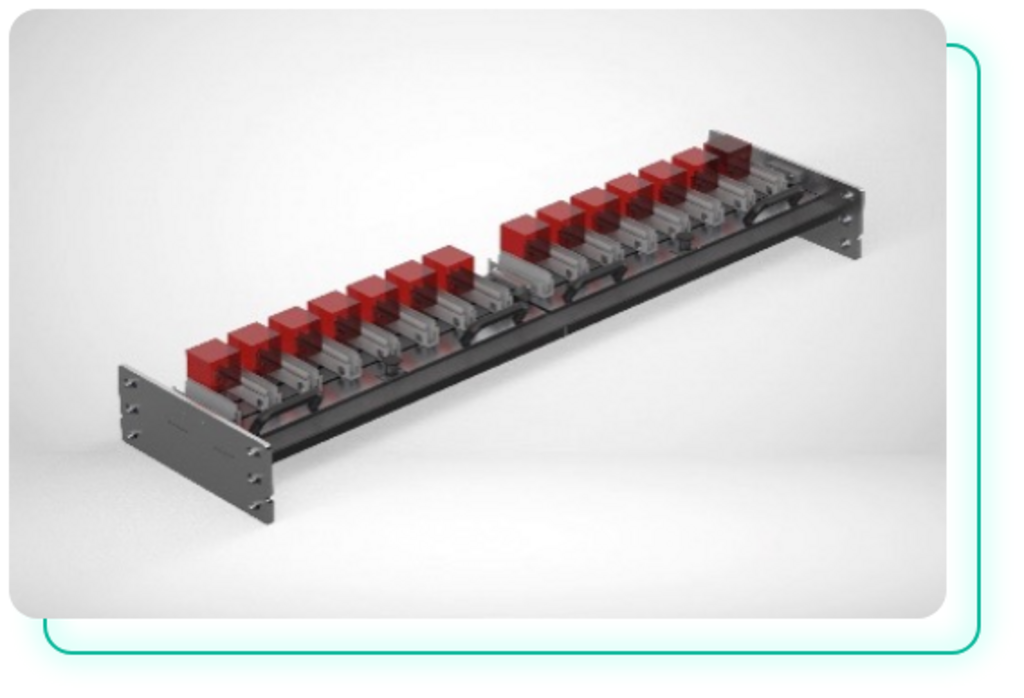

GRIPPER PREMIUM.

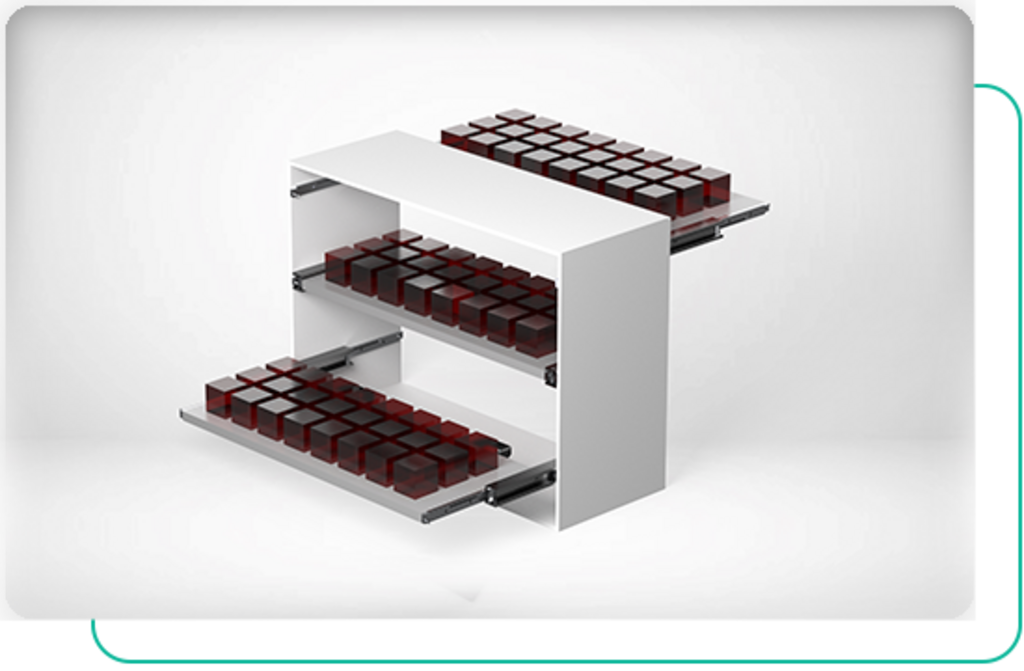

The Premium gripper is used in conjunction with the telescopic drawers. The Premium gripper can adjust to the required workpiece size without its own drive.

The gripper picks up the workpieces, which are arranged in several rows next to and behind each other on the drawer floor depending on their size, and brings them into the clamping device for clamping. The Premium gripper enables an opening path of up to 200 mm and is mainly used with the articulated arm robot solution, for example in the Indumatik VR 70.

The telescopic drawer can be used to place a large number of workpieces in several rows behind and next to each other. Hundreds of parts can be fed into the system via several drawers. This allows the processing machine to work automatically with the Indumatik for many hours.

SINGLE OR MULTI-MACHINE AUTOMATION.

A hybrid system can load either one or more milling machines simultaneously, depending on the company's requirements. This makes it possible to adapt the capacity of the system to your specific needs and thus work more efficiently.

- Unlimited number of pallet spaces: The flexible expansion option, for example by using a second machine, means that there are no limits to the number of pallet spaces.

- Large, medium and small pallet sizes: Pallet handling is suitable for a wide range of workpiece and material sizes, from small parts to large components.

- Direct handling of vices: By handling vices directly on the pallet, there is no need for an additional pallet. This not only saves costs, but also time.

- Parts and pallet handling: The pallets can not only contain the workpieces, but also individual parts or tools for further processing.

- Longer runtime of the machining center: Due to the high flexibility and efficiency of pallet handling, the machining center can work longer without interruptions, resulting in higher production output.

PALLET HANDLING.

Workpieces are clamped on pallets and stored and retrieved with the pallet in the machining center. The flexible production system is ideal for small quantities or heavy handling weights and makes it possible to automate almost all clamping systems.

PARTS HANDLING.

The pallet is not required for parts handling. The workpiece or finished part is fed directly into the machining center with a gripper. This type of automatic machine feed is recommended for large quantities with low weight.