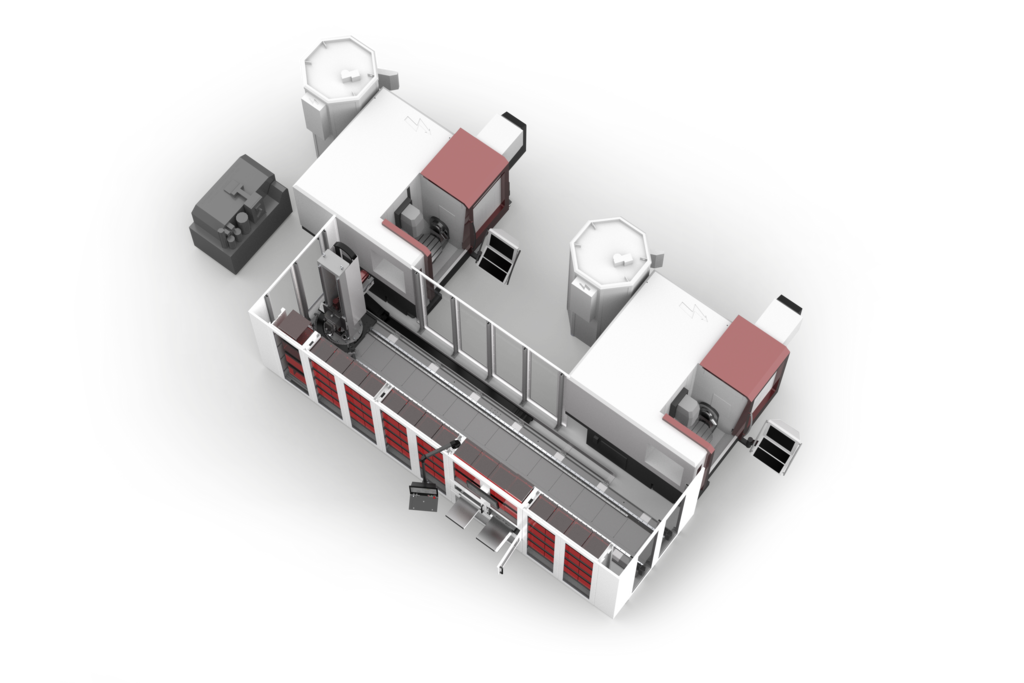

MULTI-MACHINE OPERATION.

Link several machining centers or processes with the Indumatik. There are solutions that link wire erosion machines, drying and measuring stations, for example. The Indumatik can be used not only for workpiece pallets, but also as a tool storage system. The flexible adaptation to the customer's spatial conditions should be emphasized.

PALLET HANDLING.

Workpieces are clamped on pallets and stored and retrieved with the pallet in the machining center. The flexible production system is ideal for small quantities or heavy handling weights and makes it possible to automate almost all clamping systems.

PARTS HANDLING.

The pallet is not required for parts handling. The workpiece or finished part is fed directly into the machining center using a gripper, and this type of automatic machine feed is recommended for large quantities with low weight.