ZERO POINT CLAMPING SYSTEMS.

A zero-point clamping system mounted on the table of a machining center clamps pallets and workpieces precisely and repeatably. The zero-point clamping system enables the workpieces to be positioned quickly and accurately, which improves the efficiency and accuracy of the production process. A zero-point clamping system must be used in automated operation. But it also significantly reduces set-up times in manual operation.

Depending on the machine and machine table, we have many different systems in use. Let us advise you! Below are three examples.

Increased production flexibility and a MUST for automated production

CROSS-MACHINE USE

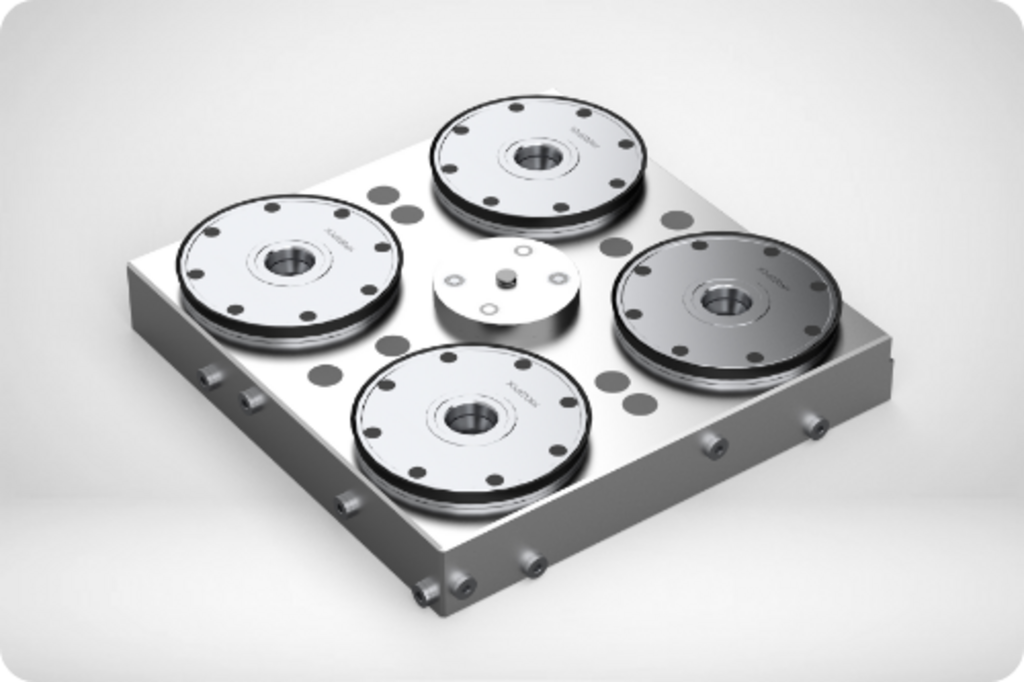

Zero-point clamping system with four opening clamping inserts for holding carrier plates and workpieces. Also available with 2-fold media feed-through for holding pre-pallets.

The zero-point clamping system (320 mm x 320 mm) consists of a base plate made of nickel-plated steel. Four clamping inserts are inserted into this base plate. Optionally with centric connection to 2-flow pneumatic rotary feed-through. A pneumatic vice can be operated via this rotary feed-through. The base plate is attached to the machine table.

Compact and powerful

HIGH POSITIONING ACCURACY

The zero-point clamping system (235 mm x 235 mm) consists of a base plate made of nickel-plated steel. Four opening clamping inserts are inserted into this base plate to hold carrier plates and workpieces. The base plate is attached to the machine table. The zero point clamping system is also available with a 2-fold media feed-through for holding pre-pallets. Optionally with centric connection to 2-flow pneumatic rotary feed-through. A pneumatic vice can be operated via this rotary feed-through.

Improved efficiency

OPTIMIZATION OF TOTAL OPERATING COSTS

Pneumatically or hydraulically controlled zero-point clamping system with two clamping inserts for holding carrier plates and workpieces. The zero-point clamping system consists of a nickel-plated steel base plate. The clamping plate is attached to the machine table.