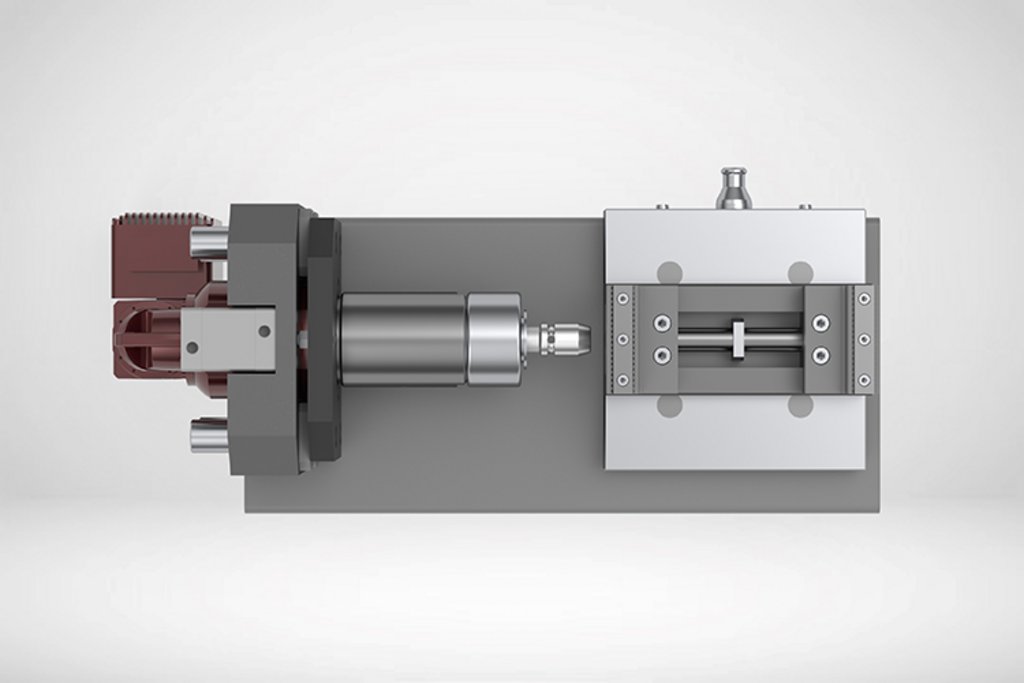

SCREWDRIVER STATION.

You can now leave the clamping to the Indumatik with screwdriving station. The electric screwdriving station automatically adjusts the vice to the required format of the workpiece. The Indumatik gripper inserts the workpiece from the rack into the vice in front of the screwdriving station and the screwdriving station clamps automatically. After the clamping process, the gripper picks up the vice with the workpiece and places it in the processing machine. The electric screwdriving station and the electric set-up station are optionally available for the Indumatik VL 40, VL 80 and VR 70 hybrid systems and the Indumatik 200.

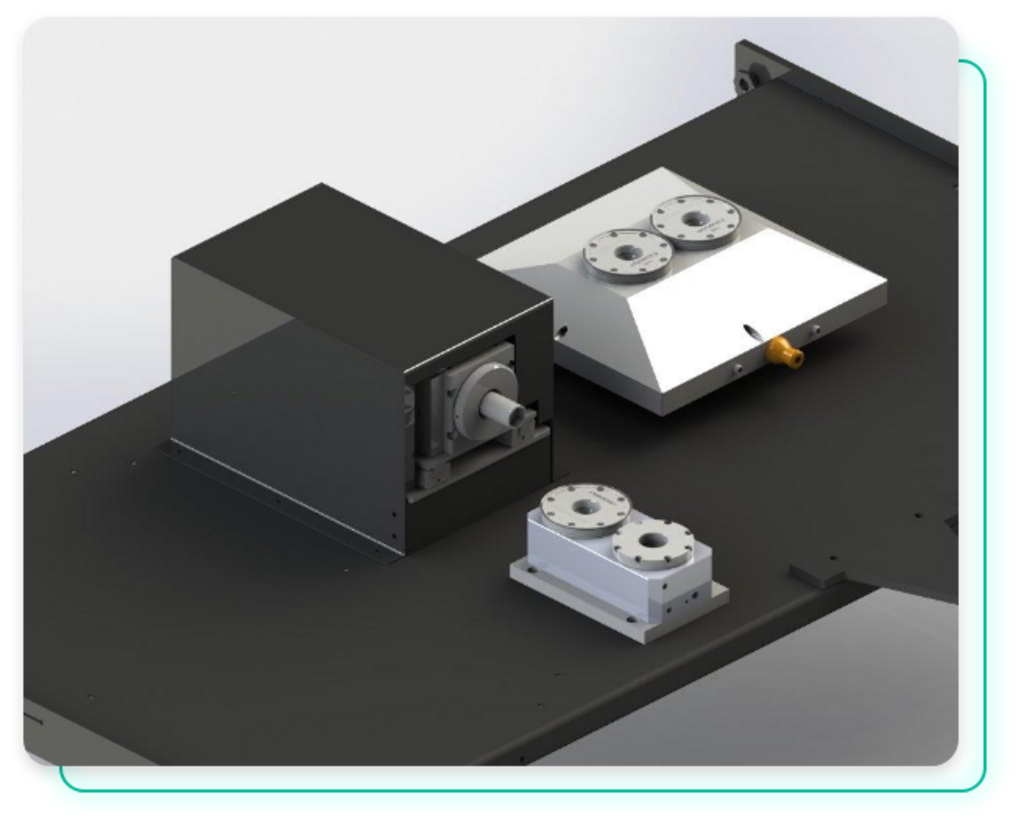

PALLET HANDLING.

Workpieces are clamped on pallets and stored and retrieved with the pallet in the machining center. The flexible production system is ideal for small quantities or heavy handling weights and makes it possible to automate almost all clamping systems.

PARTS HANDLING.

The pallet is no longer required for parts handling. The workpiece or finished part is fed directly into the machining center using a gripper. This type of automatic machine feed is recommended for large quantities with low weight.