SOFTWARE.

JOBMANAGER INDUCELL

InduCell control software for the fully automated cell.

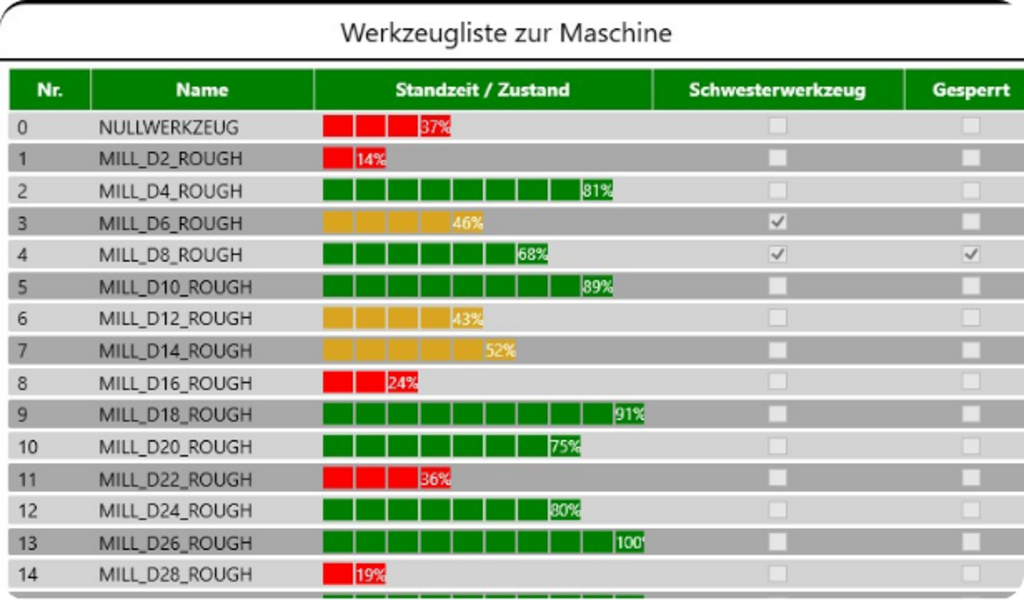

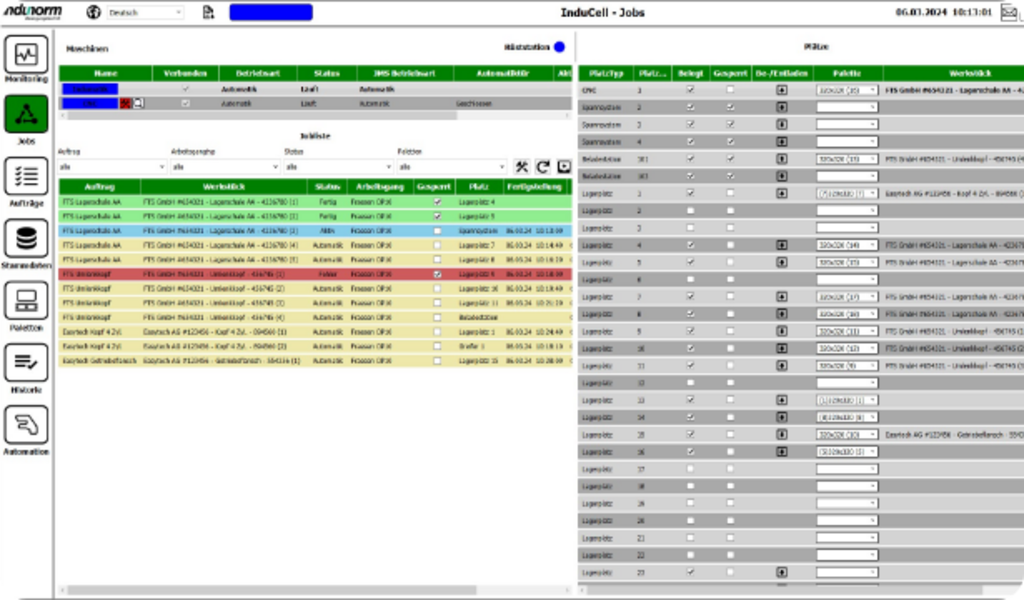

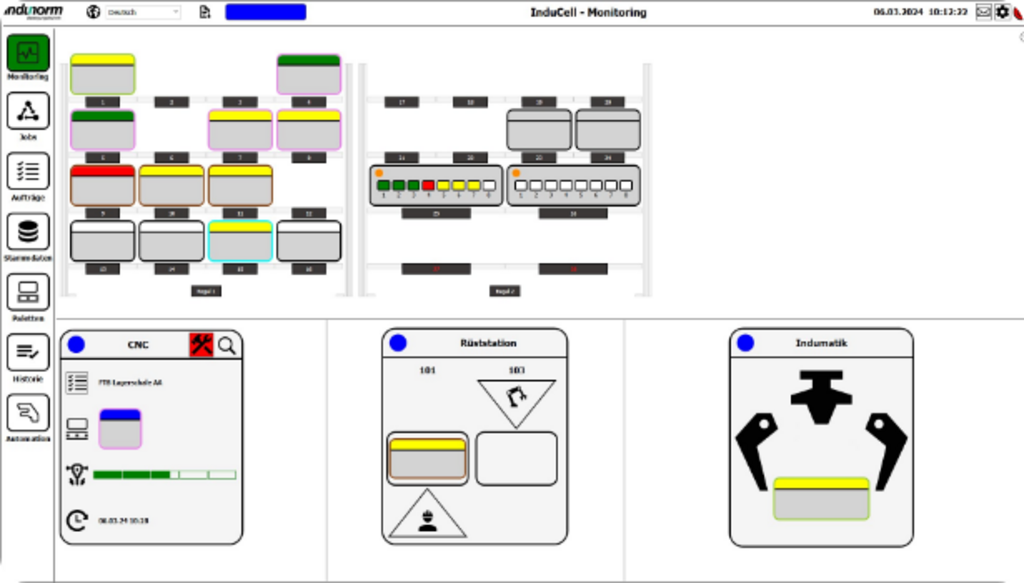

The InduCell software offers an optimum tool for planning and monitoring production in order to operate production cells efficiently. Jobs and orders are created quickly and easily via a clear user interface. The processing sequence can be edited or prioritized at any time to achieve maximum flexibility, and automatic processing adapts to the available tools. Tool usage and tool life are continuously compared so that optimum utilization is always achieved.Traffic lights visualize the status of the warehouse, the orders, the machine tool and the tools at all times so that the operator can quickly identify and implement any necessary interventions in the process. Tool life is continuously updated and compared with the required usage times of the planned jobs. The up-to-the-second display of the completion of all stored and released jobs as well as the upcoming tool requirements allows the operator to look into the future at any time.

Intuitive and efficient

EFFICIENT CONTROL AND MONITORING OF PRODUCTION BY INDUCELL

The entire production cell is controlled via our intuitive InduCell job management software. New jobs can be implemented, the system started and workpieces manufactured in no time at all. It includes numerous functionalities not only for workpiece handling (pallet and parts), but also for tool management.

Both the operator and the work planner can see at any time whether tools are available for the upcoming jobs and have sufficient tool life. To prevent downtime, InduCell continuously checks jobs, tool lists and connected machines. If intervention by the operator is necessary, the software indicates this via visual messages and colors.

Always up to date

AUTOMATED PRODUCTION AND EXTENDED NOTIFICATION FUNCTION

As the total running time of the system is always displayed and updated, automated production can be carried out unmanned overnight, around the clock and over the weekend. An app on the cell phone always shows the current status of the system.

Push notifications on various status messages or cell downtimes due to faults keep the operator informed even after work or at the weekend. The capacity utilization of the system is displayed and can be called up for downstream processes. Optional remote maintenance can be switched on to massively reduce the number and duration of service calls and downtimes.

Real-time monitoring of theprocessing machine andautomation

Analysis of themachine performance

Presentation of theenergy consumption

Remote monitoring of the machinefrom any location

Users receive warning messagesin the event of deviations or problemsin the operation of the machine

Data analysis can be used tomaintenance requirements andoptimization potential at an early stagerecognized

Simplest control

PALLET MANAGER

All Indumatik systems can be operated easily and without control software. The operator simply controls the Indumatik via the machine tool control. The NC programs remain on the machine control as usual and are linked to a pallet or location number by the operator. As soon as the NC program is called up, the machine triggers the Indumatik via an output so that the corresponding workpiece is brought into the machine. This also makes chaotic production possible with simple means, allowing existing machine tools to be retrofitted with automation without having to retrofit expensive interfaces.