INDUMATIK.

AT JONGEN WERKZEUGTECHNIK

In a world where precision and efficiency determine a company's performance, Jongen Werkzeugtechnik GmbH has secured significant advantages in production through its collaboration with Indunorm.

A strategic move to maximize production output and efficiency through innovative technologies and optimized processes.

Four decades of innovation and quality

ABOUT JONGEN WERKZEUGTECHNIK GMBH

Since its foundation in 1974, Jongen Werkzeugtechnik GmbH has established itself as a leading manufacturer of milling and drilling tools. With more than 250 employees in Germany and a continued strong presence in Europe, Jongen remains at the forefront of the industry through continuous innovation, state-of-the-art production facilities and a strong commitment to quality. Jongen is particularly proud of the fact that all products are 100% manufactured in Germany, ensuring unrivaled quality and reliability.

The challenge

The dynamic demands of the market and increasing competitive pressure led Jongen to critically evaluate the existing production bottlenecks. Longer delivery times and excessive machine utilization were the main problems, which led to an increased workload and overtime for employees. This situation not only affected employee satisfaction, but also the company's ability to respond quickly to customer requirements.

Solution

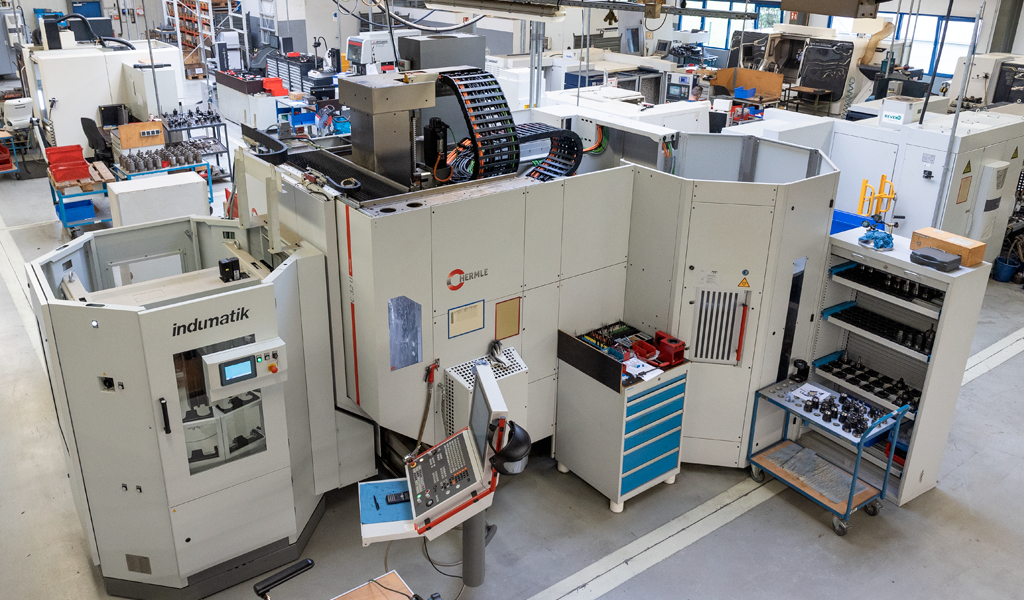

The search for an effective solution led Jongen to Indunorm's Indumatik technology. Due to the user-friendly interface, the low maintenance requirements, the excellent process reliability and the simple implementation, the choice fell on an Indumatik Ultralight. In the meantime, Jongen has automated four Hermle processing machines with Indumatik Ultralights.

RESULT.

Following the introduction of the Indumatik solution, Jongen experienced a significant increase in production. The implementation enabled shorter set-up times and improved overall efficiency of the processing machines. The team was able to continue using the existing machine programs largely unchanged, which significantly shortened the transition phase. These efficiencies resulted in increased capacity to meet demand faster and more reliably.

RETURN OF INVESTMENT

The return on investment (ROI) exceeded Jongen's expectations. Investments in the Indumatik solutions quickly paid off due to the significantly increased production figures and reduced operating costs. This cost efficiency has enabled Jongen to free up resources that can now be invested in further growth and the development of new products.

Customer feedback

"Working with Indunorm has not only improved our production capacities, but also significantly increased the job satisfaction of our teams. The straightforward implementation and robust performance of the Indumatik solution have made a significant contribution to our company's success. We look forward to a continued and fruitful partnership with Indunorm."

Uwe Schlienkamp

Head of the Carrier Tool Production Department Jongen Werkzeugtechnik GmbH