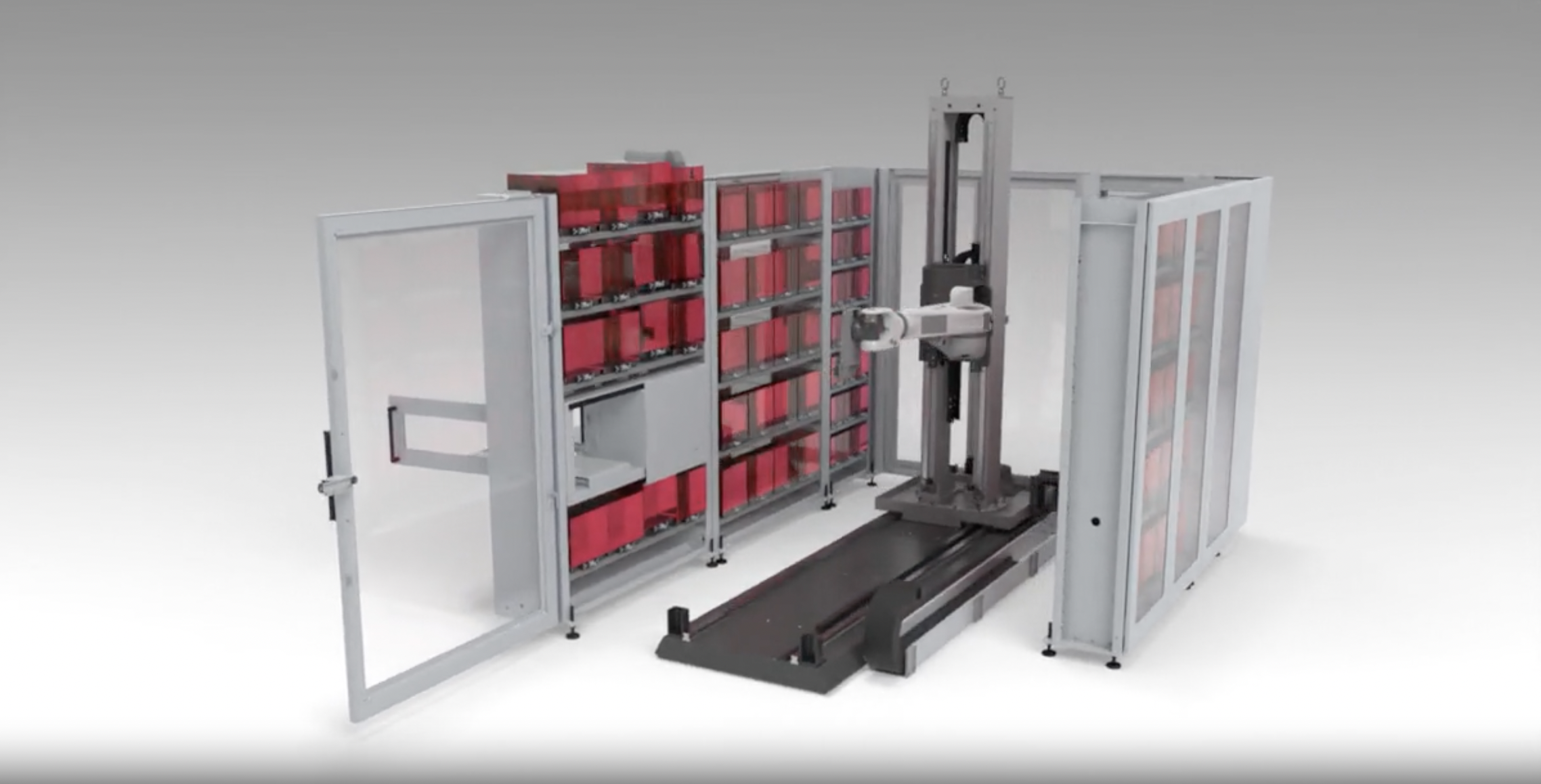

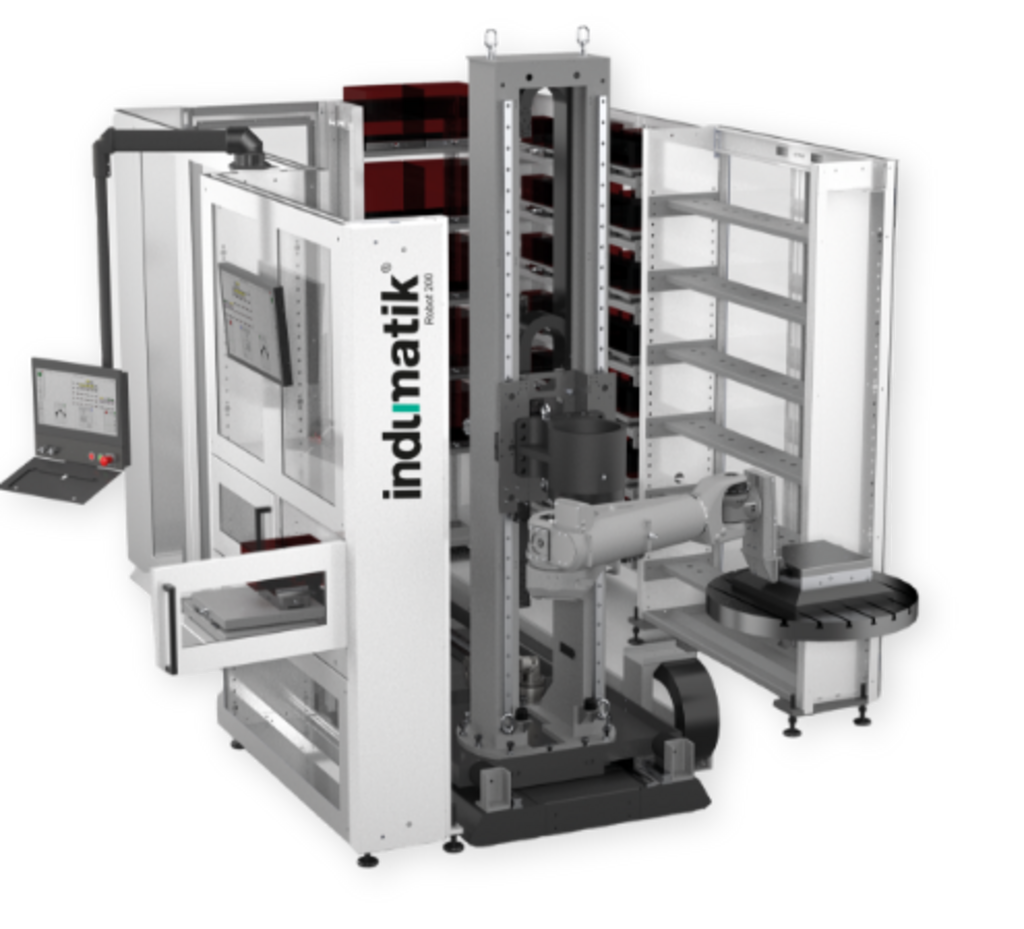

INDUMATIK - R 200.

Half scara - half linear axis system

Half of our Indumatik R 200 linear axis robot consists of a Scara arm and the other half of a linear axis system. This is moved on the floor by a specially developed 7th axis. The system is characterized by a very compact design and a long reach. Depending on the project, the footprint of the system is reduced by around 50% compared to a conventional articulated robot and the available space can be used on several levels thanks to a vertical linear axis. In addition, we are independent of the control system manufacturer and the machine manufacturer can control the system with its existing control system and therefore does not need its own robot controller. This makes the application very lean and simple for both the customer and the service department

|

Dimensions [WxDxH] |

3700 x 2800 x 3000 mm |

|

|---|---|---|

|

Permissible transfer weight |

200 kg |

|

|

Pallet gripper |

zero-point gripper |

|

|

Sub gripper or gripper options |

parallel gripper, fork gripper, tool gripper |

|

|

Storage location size [W x D] in standard |

30 x 30 mm, 200 x 200 mm, 320 x 320 mm, 400 x 400 mm |

|

|

Pallet spaces as standard |

46, individually expandable |

|

|

Job management operation |

touchscreen optional master computer |

|

|

Interface |

Io interface / Profibus / ... |

|

|

Storage/retrieval of the WS |

storage and retrieval station |

|

|

Multi-machine operation |

Flexibly expandable |