GRIPPER SOLUTIONS.

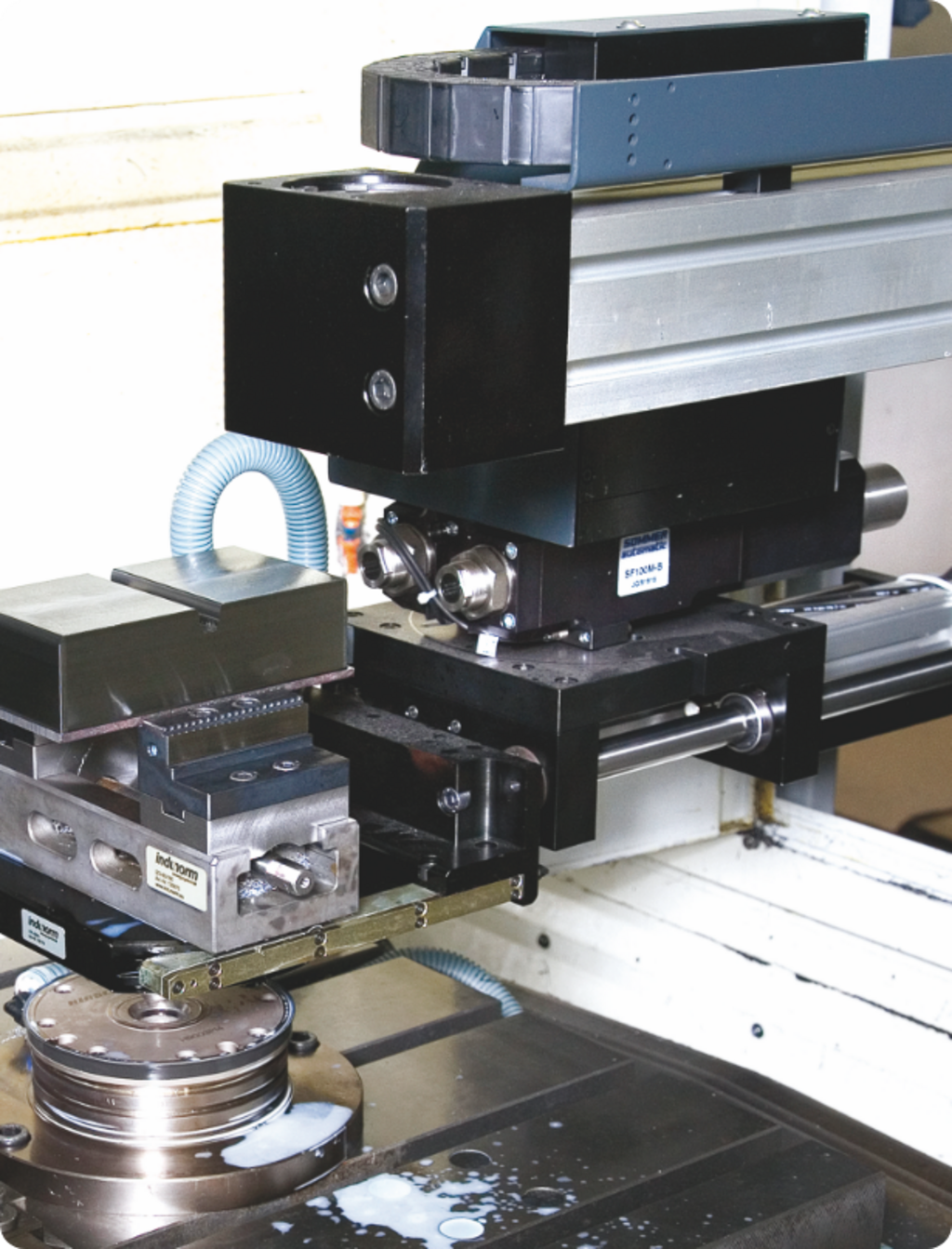

The sub-grippers are necessary to:

- different pallet sizes,

- tools,

- direct workpiece handling,

- direct handling of the clamping device (e.g. vice )

in one system. This allows the Indumatik to work flexibly and automatically and is not limited to one pallet size or part size.

The necessary sequence is created once for each workpiece in the software. If the workpiece is to be produced repeatedly, everything is already described for the workpiece and the process can be started in just a few steps. Standardized automation solutions on the market often only have one main gripper, which can usually hold pallets. Mixed operation of different sizes and workpieces is often not possible.

We offer this option by using sub-grippers, thereby increasing the autonomous running time of the automated machine. The advantage is that different pallet sizes and workpieces can be processed overnight. The system is not limited to one series part.